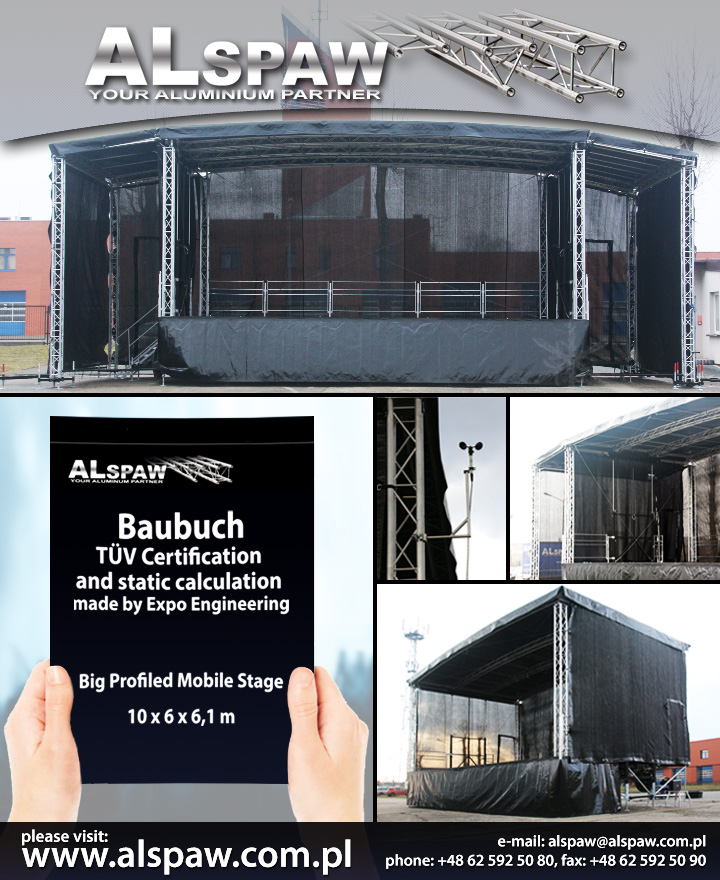

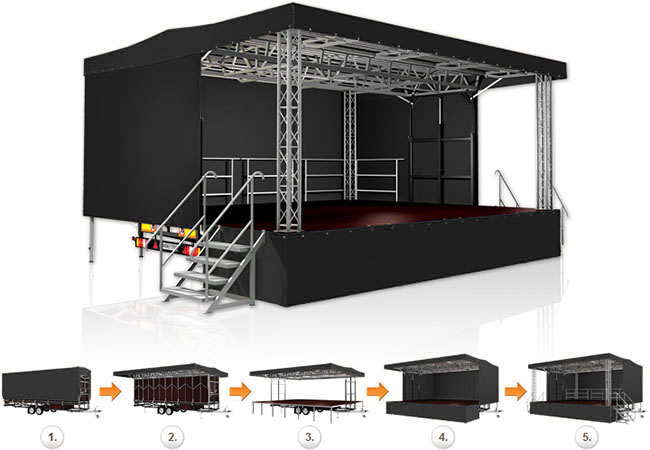

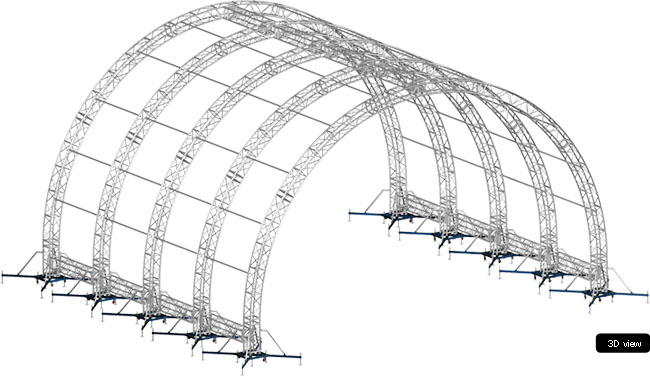

Standard S24 Plus mobile stage 6x4x5m

Standard Mobile Stage S24 it’s the latest size in our offer of mobile stages. S24 Mobile Stage was designed according to EUROCODE 0, 1, 3, 9, as well as all mobile stages, produce by ALSPAW. Mobile stage can be used for speeches, political campaigns, literary books promotion and small events. All accessories and additional elements should be transported separately on the truck.

|

Technical data |

|

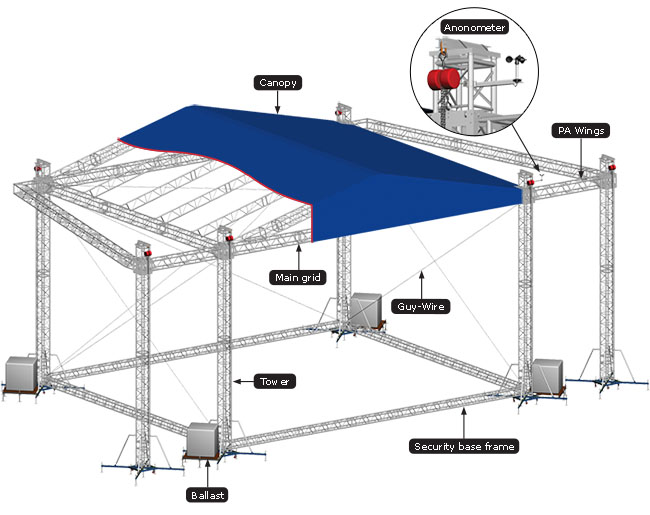

| Type of roof | standard |

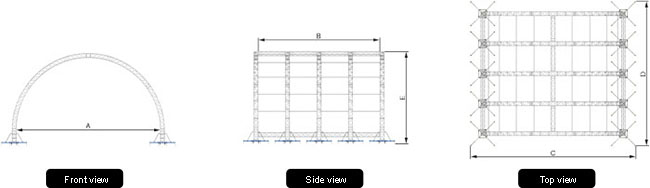

| Dimensions as a stage | 6,0 m x 4,0 m x 5,0 m |

| Dimensions as a trailer | 7,4 m x 2,45 m x 3,6 m |

| Permitted total weight | 2500 kg |

| Stage area | 24 m2 |

| Height of stage floor | 1,0 - 1,3 m |

| Stage floor | slip proof, weather proof |

| Roof capacity |

30 kg - uniformly on front and back part of the roof (the end tube) 240 kg - uniformly on front and back part of the roof (the middle tube) 420 kg - uniformly on the middle part of the roof |

| Floor capacity | 3,5 kN/m2 (ok.350 kg/m2) |

| Quadrosystem front pillars load capacity | 50 kg |

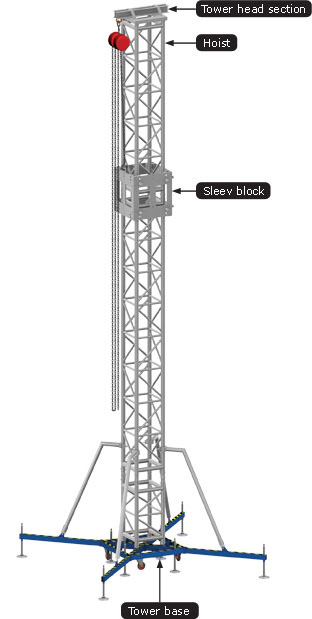

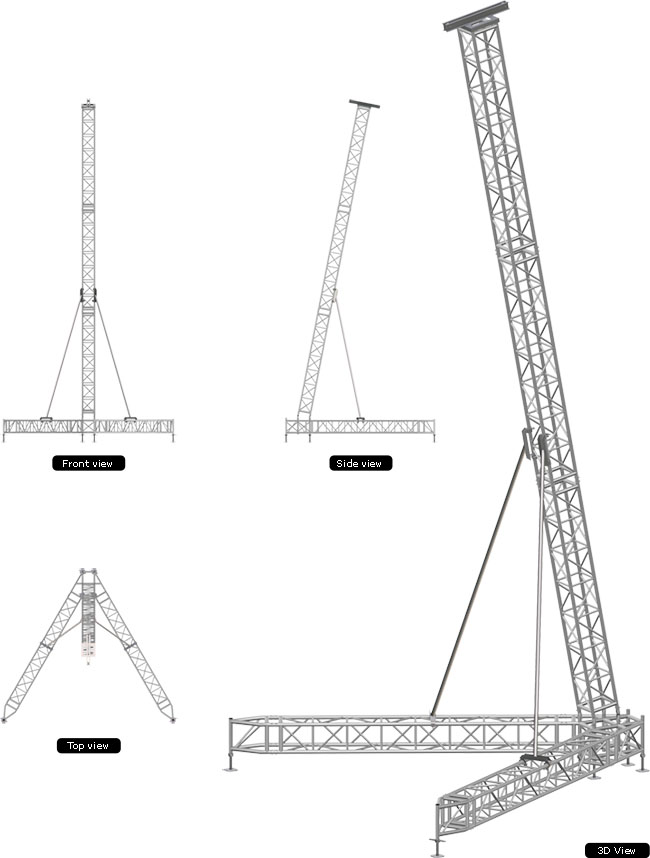

| Flying Towers load capacity | 250 kg (in the middle point) |

| Max. wind speed | Wind zone 1 – 3 excepting the 5 km wide coastal areas and the islands of the North Sea and the Baltic Sea:. max 17.8 m/s with the back and sides cover and max 30 m/s without cover |

| Max. thickness of snow on the roof | Mobile stages should be used only in periods in which there is no snow, unless the snow is effectively removed, e.g. by installing the appropriate heating devices |

| Canopy | PCV certified material (flame resistant) |

| Scrim | A203 (white or black) |

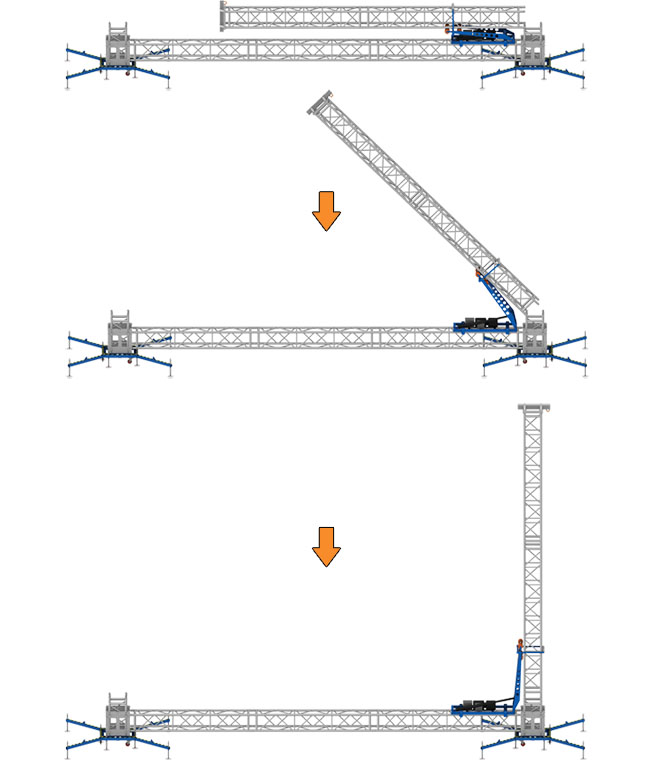

| Installation time | 30 min (1-2 people) |

| Equipment | |

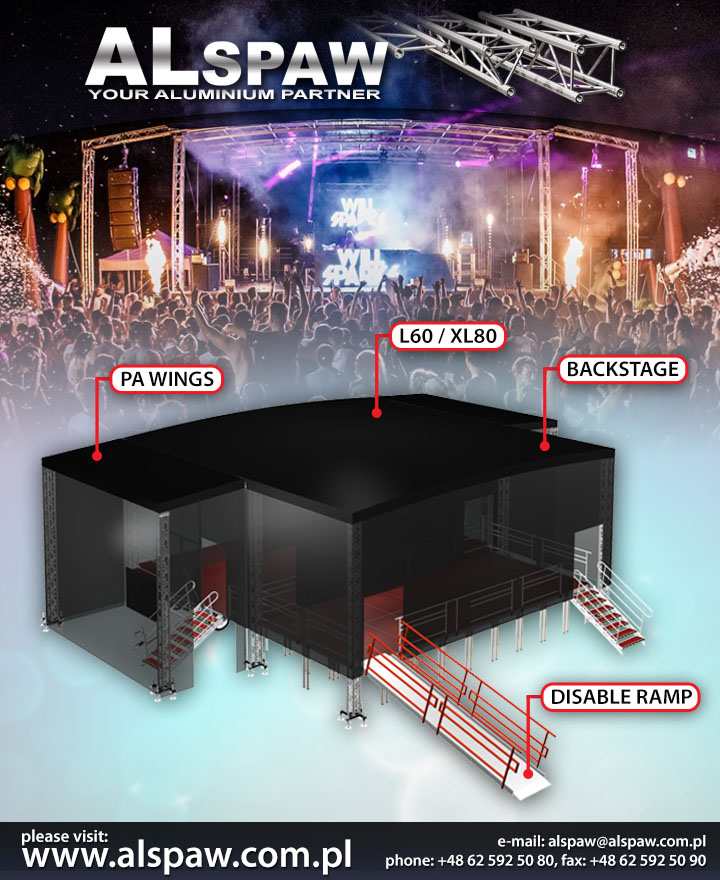

| Basic accessories and options |

- PVC canopy for the roof - Scrim for back and sides (2/3) - Down covering PVC canopy - Truss pillars (Q250, 50x2) x 4 pcs - Standard stairs x 2 pcs - Rails for 3 sides - Spare parts - Manual hydraulic system of lifting up the roof - Manual system of leveling the floor |

| Additional accessories and options |

- Crossed legs - Flying towers - PA Speakers - Ramp (top made of plywood) - Stage cover - Scrim side extension till front pillar (1/3) on velcro - 2 pcs - Small storage canopy for closing front and back of mobile stage - Galvanized chassis - Electric hydraulic lifting up the roof by remote control - Electric hydraulic lifting up the roof by remote control and electric leveling stage floor by remote control |